| OPTIMISATION of curved insulating glass panels |

| English Section Publicat de Ovidiu Stefanescu 31 Aug 2016 09:55 |

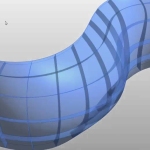

Using irregular or curved geometric forms for curtain walls projects, especially in their window areas, it has become a fairly common practice in contemporary architecture. Through these solutions are aimed mainly an increase the structural efficiency, being useful when these panels are subjected to impact with objects or external loads. Due to the increased rigidity of such forms, the pressure in the assemblies becomes more sensitive compared to classical situations, what often causes further strains manifested in edge areas where sealing cords are applied. Given the lack of analytical or empirical solutions to refer the most curved forms and estimate the existing pressure in the interstices of these assemblies, the calculations are made using finite tools analysis. The ultimate goal is to develop a useful parameter method to design this kind of structures. The procedure involves combining elementary methods with an optimization of manufacturing processes. This latter task, that must be assumed by the design tool, has a major role to calculate the minimum thickness of the glass elements - information needed to be obtained by combining the resistance to climatic loads supported the finished product during the operation. The program is particularly useful in the early stages of design, when geometric shapes record frequent changes and when trying to achieve a balance between the characteristics of transparent components - by their nature, quite fragile - and the height of building. Usually, when an insulating glass (IGU) with two or three sheets of glass is manufactured (the cavity of which is hermetically sealed), the volume of gas inside is constantly under specific conditions of temperature and humidity. After moving from the manufacturing place to the installation site, changes in altitude, atmospheric pressure, temperature etc. can generate changes of relative pressure (the ratio of the existing pressure in the cavity and the atmospheric one), causing some distortions that remain until the rebalance the original state (the so-called "pillowing effect"). Using irregular or curved geometric forms for curtain walls projects, especially in their window areas, it has become a fairly common practice in contemporary architecture. Through these solutions are aimed mainly an increase the structural efficiency, being useful when these panels are subjected to impact with objects or external loads. Due to the increased rigidity of such forms, the pressure in the assemblies becomes more sensitive compared to classical situations, what often causes further strains manifested in edge areas where sealing cords are applied. Given the lack of analytical or empirical solutions to refer the most curved forms and estimate the existing pressure in the interstices of these assemblies, the calculations are made using finite tools analysis. The ultimate goal is to develop a useful parameter method to design this kind of structures. The procedure involves combining elementary methods with an optimization of manufacturing processes. This latter task, that must be assumed by the design tool, has a major role to calculate the minimum thickness of the glass elements - information needed to be obtained by combining the resistance to climatic loads supported the finished product during the operation. The program is particularly useful in the early stages of design, when geometric shapes record frequent changes and when trying to achieve a balance between the characteristics of transparent components - by their nature, quite fragile - and the height of building. Usually, when an insulating glass (IGU) with two or three sheets of glass is manufactured (the cavity of which is hermetically sealed), the volume of gas inside is constantly under specific conditions of temperature and humidity. After moving from the manufacturing place to the installation site, changes in altitude, atmospheric pressure, temperature etc. can generate changes of relative pressure (the ratio of the existing pressure in the cavity and the atmospheric one), causing some distortions that remain until the rebalance the original state (the so-called "pillowing effect"). |

ABONARE REVISTA (click aici): PROIECTE | INVESTITII | REVISTE | INDEX COMPANII

DATE DE CONTACT: Agenda Constructiilor & Fereastra - Tel/Fax: 021-336.04.16, 031-401.63.88

Documente

01 sep 2020

17 feb 2020

13 sep 2019

13 sep 2019

.gif)